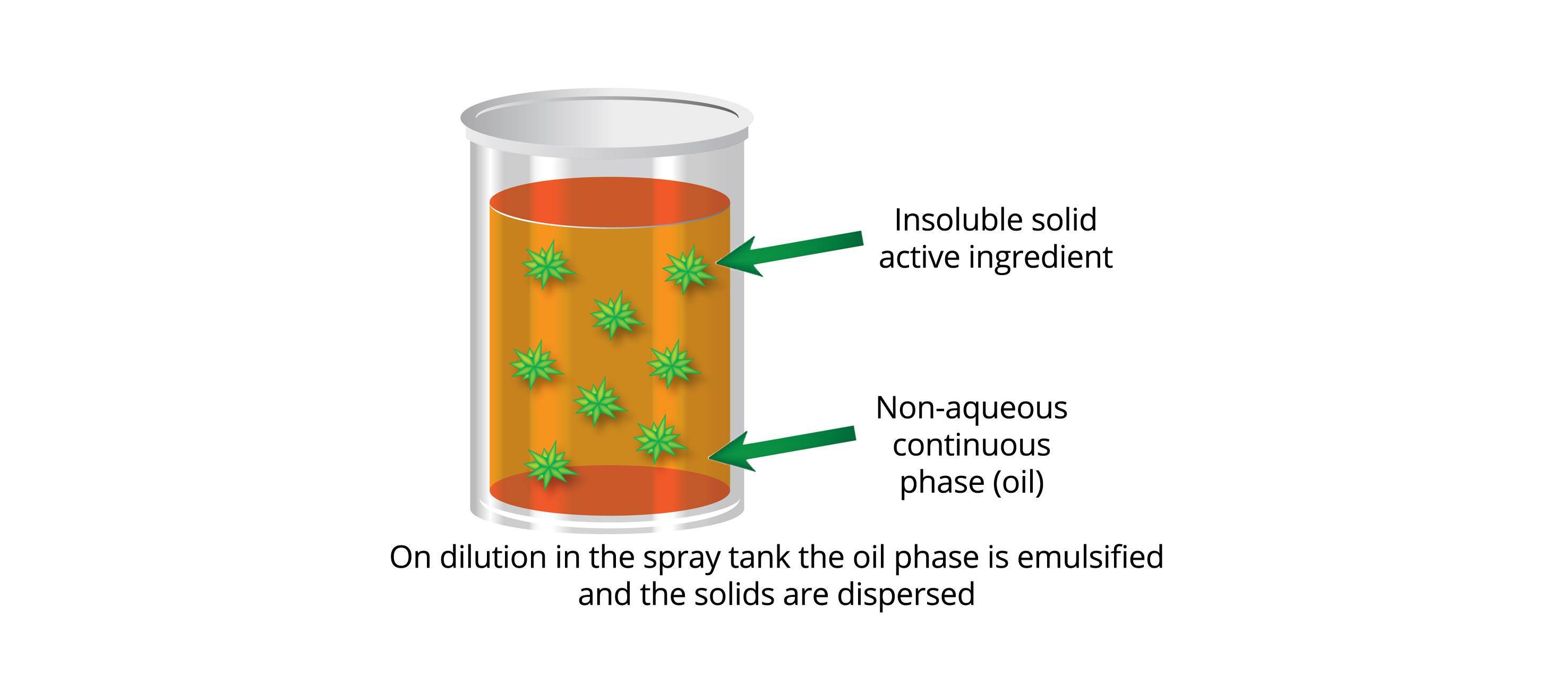

Oil dispersion (OD)

An oil dispersion (OD) formulation is a solid active ingredient dispersed in oil. The oil can vary from paraffinic to aromatic solvent types and vegetable oil or methylated seed oils. Ideally the active ingredient is uniformly suspended in the oil phase.

ODs are an excellent delivery system for water sensitive active ingredients such as sulfonylureas. However, ODs have extended to other active ingredients due to their better spray retention, spreading and foliar uptake as the carrier oil often acts as an adjuvant.

Benefits

- Especially suited to hydrolytically unstable actives allowing them to be formulated as liquid formulations

- The oil continuous phase acts as a built-in adjuvant

- The oil adjuvant can provide both penetration enhancement and spray retention enhancement

- Does not need preserving (water free)

Limitations

- Can suffer from more sedimentation compared to water based systems

- Difficult to formulate

The Formulator's Toolbox (Full Version)

Oil Dispersion Step-by-Step Guide

Formulating Nicosulfuron as an Oil Dispersion

Developing microbial oil dispersion (OD) formulations

Products recommended for OD

Aqueous dispersants are used in some cases in order to improve stability in the spray tank after dilution in water. If the active ingredient is insoluble in water and needs to be suspended for a length of time, the aqueous dispersant will prevent flocculation of these solid particles and improve overall stability.

.jpg&mn=cropcare&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=BE08314A4FD370F810F45D699E14893C19C138999FEC74AA)

Atlox Metasperse™ 550S

Atlox™ 4915

Emulsifiers are necessary in order to emulsify the continuous oil phase into water when the OD formulation is diluted prior to being sprayed. Emulsifiers are selected based upon their ability to spontaneously form this emulsion. Their performance is primarily dictated by the nature of the surfactant and their collective effect on how they arrange themselves at the oil/water interface.

Atlas™ G-1086

Atplus™ 300F

Atplus™ 309F-LM

Atlox™ 4838B

Non-aqueous dispersants disperse the active ingredient in the oil continuous phase and provide long term stability. In an OD formulation, solid particles are susceptible to flocculation, leading to an increase in particle size and formulation instability. To prevent this, the use of a polymeric dispersant is highly recommended.

Atlox™ 4916

Atlox™ 4914

Atlox™ LP-1

Zephrym™ PD2206

Oil composition and quality may impact formulation performance either upon production or upon extended storage. Variations from oil to oil can commonly occur depending on the source so strict specifications should be applied to the chosen oil and stuck to throughout the lifetime of that material. Croda’s range of Seatons Refined Oils are 100% natural and renewable. They are also impurity free and have a good compatibility with many active ingredients, making them great options for crop care formulations.

.jpg&mn=cropcare&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=BB9E08CCA29C7EA9890679CCAB89BACB19C138999FEC74AA)

Seatons refined linseed oil

Seatons refined rapeseed oil

.jpg&mn=cropcare&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=FA57C23FA84273041BD2372576E0B85719C138999FEC74AA)

Seatons refined soyabean oil

Rheology modifiers are an essential part of an OD formulation. If the formulation is not stabilised effectively, the solid active ingredient(s) will sediment forming a hard pack layer preventing re-dispersion. A common way to reduce this sedimentation is to increase the viscosity of the continuous phase using a rheology modifier.

.jpg&mn=cropcare&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=95EA288BC8762DCB34DEC3D4091BDF0419C138999FEC74AA)

Atlox Rheostrux™ 100

.jpg&mn=cropcare&w=768&xr=0&yr=0&xfp=6&yfp=6&hash=11B8A71797BADCC24ACDC1145A3EB96519C138999FEC74AA)